Barcode Verifiers Cognex Automated

Barcode verification plays a crucial role in ensuring the smooth functioning of automated systems. With the rapid advancement of technology, barcode scanning 1d and 2d and verification have become integral parts of various industries, such as manufacturing, logistics, and retail.

Features and Specifications

Detailed Reporting for Quality Control

Dive into the advanced data matrix reporting capabilities of Cognex verifiers, offering businesses comprehensive data matrix analyses and documentation for quality control and compliance audits.

Versatile Barcode Options and Applications

Discover the flexibility of Cognex verifiers, supporting a wide array of barcode verifier symbologies and catering to diverse industry needs, from product labels to shipping labels.

User-Friendly Interface and Operation

Explore the user-friendly design and intuitive operation of Cognex bacode verifiers, suitable for both experienced operators and newcomers to barcode verification systems.

Efficiency and Reliability in Barcode Scanning

Understand how Cognex combine cutting-edge features and versatility to streamline barcode verifiers and scanning processes, ensuring accurate data capture and improving overall operational productivity.

Barcode verifier 's Benefits

Enhance accuracy

First and foremost, Cognex 1d and 2d barcode verifiers significantly enhance accuracy in barcode scanning. By thoroughly analyzing settings and verifying compliance with industry standards, these 2d barcode verifiers can minimize the risk of misreads and errors in data capture.

Operational efficiency

In addition, Cognex barcode verifiers boost operational efficiency quality by streamlining processes. By automating barcode verification, businesses can eliminate manual verification steps and human intervention, reducing the overall time and effort required for quality control.

Cost savings

Another notable benefit of Cognex verifiers is the potential cost savings they bring to businesses. By preventing errors and ensuring proper labeling and tracking of products, companies can avoid potential losses associated with inaccurate data, misreads, or non-compliant barcode verifiers.

How Cognex Verifier Ensure Accurate Barcode Scanning

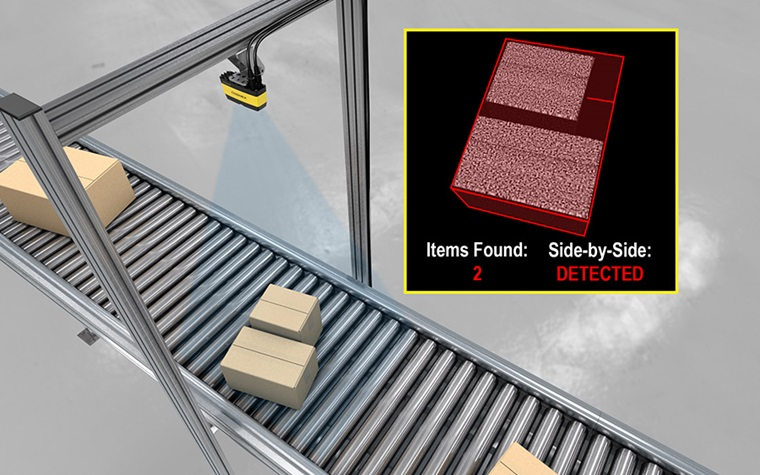

Image-based code reading

One of the key technologies utilized by Cognex verifier is image-based code reading. Unlike traditional laser scanners and code others, image-based laser scanner and code readers capture the entire barcode verifiers image of direct part marked Data Matrix symbols according to the ISO IEC 29158 standard for checking the quality of those marks, enabling more comprehensive analysis and verification quality.

Powerful algorithms

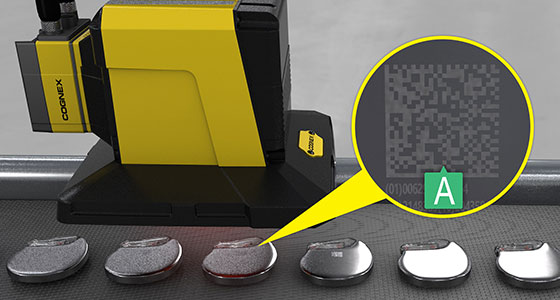

Cognex verifiers also leverage powerful algorithms for barcode verifiers analysis and decoding. These algorithms can verify barcodes and differentiate between the barcode and background noise, filter out disturbances, and extract the barcode data accurately.

Adjustable settings and parameters

Furthermore, Cognex verifiers offer high quality performance handheld solution with maximum width adjustable settings and parameters to optimize barcode scanning for specific applications. Users can configure parameters such as exposure time, gain, and lighting conditions to adapt to different barcode verifiers types and environments. Barcode reader with its direct part marks has a calibration card, symbol contrast and suggest remedial actions based. The right barcode verifier give quality detailed report that can reduce errors with its two dimensional auto optic scanner code.

Various barcode symbologies

Cognex verifiers are designed to handle various barcode symbologies, including verify small linear barcodes, codes, 1d and 2d other linear barcodes, 2D barcode, codes, qr code and postal codes.

Barcode verification Key Considerations for Choosing the Right Cognex Verifiers

Application and barcode verifiers type

Determine the specific application and barcode types that the verifier needs to handle. Different Cognex verifiers excel in different barcode verifiers symbologies, sizes, and printing technologies. Assess the compatibility and suitability of the verifier for the targeted barcode applications.

Performance and throughput requirements

Evaluate the required scanning speed and throughput of shoot verifier for the intended application. Consider factors such as high performance handheld solution, symbology specifications, iso specifications, automatic variable aperture, print quality, scanning volume, processing speed, and overall system performance. Select a Cognex verifier that can meet the desired performance levels without compromising accuracy read quality print quality either.

Industry standards compliance

Ensure that the chosen Cognex verifier complies with the relevant industry standards for barcode verifier quality. Consider standards such as relevant iso iec and ANSI for barcode verification. Selecting a barcode verifier that meets these standards ensures compatibility and interoperability in the supply chain and to optimise business money.

Ease of use and integration

Assess the ease of installation, operation, and integration of the Cognex verifier with existing systems and workflows. Look for verifier with user-friendly interfaces, straightforward setup procedures, and compatibility with common software platforms or connectivity options.

Scalability and future-proofing

Consider the scalability and future needs of the business. Choose a Cognex verifier that offers expandability options, allowing for potential growth and evolving barcode verifier auto optic laser scanner and requirements. Future-proofing the selection ensures long-term viability and return on investment.

Support and maintenance

Evaluate the level of technical support and maintenance services provided by Cognex. Consider factors such as warranty, service agreements, and availability of technical resources. Reliability and accessible support contribute to the overall success of the implementation.

By carefully considering these factors, businesses can select the most suitable Cognex barcodes verifier for their specific needs. Choosing the right barcode verifiers to either verify small linear barcode or verify linear barcodes or verify large linear barcodes, iso iec, or also ensures optimal performance, accuracy, and compatibility with industry requirements, ultimately maximizing the benefits and value obtained from Cognex's barcode verification solutions.

Get a free consultation with Mécatronique Solutions.