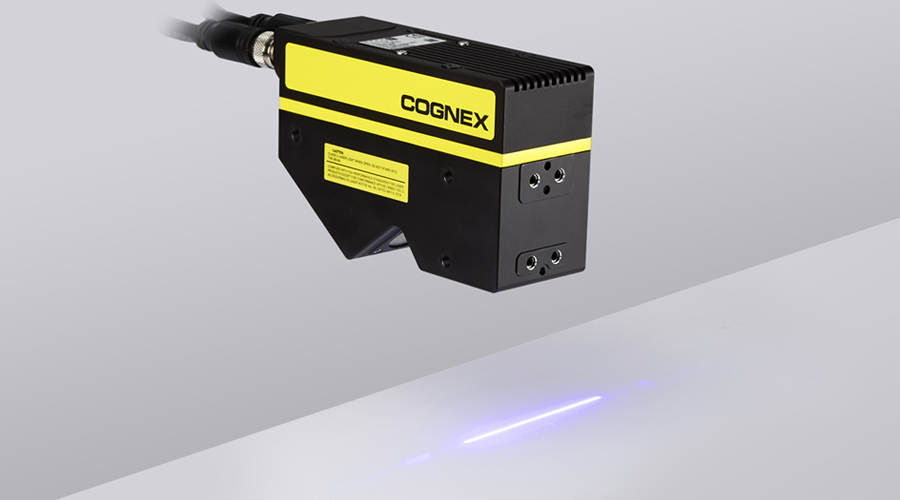

3d machine vision camera

Cognex 3D machine vision cameras employ cutting-edge tech to automate inspection, measurement, and quality control processes across industries. Integrated into production lines, they swiftly detect defects using structured light projection, time-of-flight, and stereo vision, enhancing performance and productivity while ensuring high-quality output. This innovation revolutionizes manufacturing, optimizing processes, and elevating quality control standards.

Features of 3D Machine Vision Cameras

Hardware and Software Fusion

Cognex 3D machine vision cameras leverage and create a synergy between hardware components and advanced software algorithms. They operate by employing various techniques to capture and process visual information, crucial for generating precise 3D object representations.

Structured Light Projection

One prevalent method involves structured light projection, where patterns are projected onto the object. Analyzing the deformed light pattern allows the camera to calculate object depth, orientation, position, orientation and shape through intricate algorithms.

Time-of-Flight Technology

Time-of-flight technology measures light travel time to and from the object. By interpreting time delays, the camera determines distances between objects and constructs 3D models of the position of objects based on this data.

Stereo Vision Techniques

Utilizing multiple angles of an object, stereo vision mimics the experience of human depth perception. Varied perspectives captured enable depth calculations, contributing to the creation of comprehensive 3D representations of objects.

Advanced Software Analysis

Upon acquiring 3D data, we use specialized software algorithms process and scrutinize object properties or flaws. Customizable algorithms empower producers with accurate measurements, precise defect identification, and tailored quality control functions.

Benefits of Using 3D Machine Vision Cameras in Quality Control

Save costs in production processes

In addition to accuracy features, other features of these cameras improve efficiency and save costs in production processes. The speed and automation capabilities of 3D machine vision cameras allow for high-speed inspection of products, significantly up effectiveness by reducing inspection times and increasing throughput. By automating inspection tasks, producers can save on labor costs and allocate resources to other critical areas of production.

Real-time defect detection and automatic rejection

Furthermore, 3D machine vision cameras enable real-time defect detection and automatic rejection of faulty products from the production line. This immediate feedback helps prevent the delivery of defective goods to customers, reducing the potential for product returns and associated costs. By eliminating defective products early in the manufacturing process, these cameras help maintain product quality, protect brand reputation, create, and reduce the overall cost of poor quality in production.

Valuable data and insights

Moreover, utilizing 3D machine vision cameras in quality control processes provides producers with valuable data and insights. The cameras capture detailed information about the dimensions, shape, and surface characteristics of products. This data can be analyzed to identify process improvements, optimize production parameters, and enhance overall product design and performance.

Choosing the Right 3D Vision Camera for Your Application

Accuracy, reliability and precision of the camera

Another key factor is the accuracy, soundness and precision of the camera. Different cameras have varying levels of accuracy, which can impact the credibility, reliability and quality of your measurements or inspections. It's essential to evaluate the specifications provided by the camera manufacturer and ensure they align with your application's requirements. Additionally, consider the trustworthiness, repeatability and stability of the camera's measurements over time, as this can affect the consistency and consistency of your results.

Compatibility with your existing systems

Compatibility is another critical aspect to consider. Ensure that the selected 3D vision camera integrates seamlessly with your application or existing systems, such as software platforms or robotic arms. This includes compatibility with connectors, communication protocols, and software interfaces. Compatibility is crucial for smooth integration and avoiding compatibility issues that could potentially disrupt your operations or limit functionality.

Field of view, scanning speed, and lighting requirements

Other factors to consider include the field of view, scanning speed, and lighting requirements of the camera. The field of view should be appropriate for capturing the entirety of the items you are inspecting or measuring. The scanning speed should align with your production speed to ensure real-time inspection and minimize bottlenecks. Additionally, consider the lighting requirements for optimal image capture. Some cameras may require specific lighting conditions or additional accessories to ensure accurate and consistent results.

Integrating 3D Machine Vision Cameras with Robotic Systems

Vital visual data

By incorporating 3D machine vision cameras into robotic systems, there's a notable enhancement of experience in robotic guidance. These cameras furnish vital visual data regarding the subject's whereabouts, empowering the robot to precisely identify, find, and handle items. This capability enables robots to execute intricate tasks like precise picking, assembling, or packaging operations. Leveraging the 3D information obtained by the cameras, robots can adjust to differences in object positioning, size, or placement, ensuring consistent and dependable performance.

Greater flexibility and adaptability

Additionally, the integration and use of 3D machine vision cameras and robots allows for greater flexibility and adaptability in manufacturing processes. The cameras provide real-time feedback during robotic operations, enabling dynamic adjustments to accommodate variations in the environment or product specifications. This flexibility allows for efficient handling of different subjects and reduces the need for manual intervention or reprogramming when changes in the production line occur.

Common Challenges and Solutions in Implementing 3D Machine Vision Cameras

One of many challenge in implementing 3D machine vision cameras in industrial applications is overcoming environmental factors that can interfere with the camera's performance. Factors such as temperature variations, dust, vibrations, or noise can affect the accuracy and dependability of the captured data. Implementing protective measures, such as temperature-controlled enclosures, dust filters, or vibration dampeners, can help mitigate these issues and maintain consistent camera performance. Moreover, conducting regular maintenance and calibration routines to ensure optimal functioning of the cameras is essential for long-term reliability and accuracy.

By addressing these common challenges through proper lighting setups, environmental considerations, and software solutions, the successful implementation and use of 3D machine vision cameras can be achieved, enabling manufacturers to realize the full potential of these advanced imaging systems for their industrial applications.

Importance of 3D Machine Vision Cameras in Industrial Applications

In industrial settings, 3D machine vision cameras are pivotal. They can manufacturers streamline quality control by precisely identifying defects and inconsistencies, reducing errors, and productivity and ensuring top-notch quality for Cognex products.