Cognex vision systems

Innovative applications of machine vision systems in manufacturing process

Cognex' vision inspection systems are cutting-edge solutions that integrate advanced imaging technology, computer hardware, and machine vision algorithms to automate visual inspections and quality control processes in industrial settings.

These systems utilize high-resolution cameras, powerful software, computer hardware, and customized lighting setups to capture and analyze images or video streams of products or components, enabling automatic identification and verification of issues, measurements, and other quality parameters.

With a long-standing reputation as a leading provider of industrial vision systems, Cognex offers a wide range of solutions tailored to various manufacturing applications many industries.

These systems have revolutionized the way companies and industries approach quality control, streamlining industrial production processes to reduce costs and minimizing defects.

What is a machine vision system?

A Machine vision inspection system consists of several key electronic components working together to perform accurate and efficient inspections.

High-resolution cameras

At the heart of the whole vision inspection system are high-resolution cameras that perform image capture or video streams of the products or parts under inspection.

These cameras can be configured to capture light from multiple angles or for light in different spectral ranges, depending on the requirements of the application.

Specialized software

The captured images or video streams are then processed using specialized software, such as Cognex VisionPro, for example, which applies advanced algorithms for pattern recognition, image analysis, and defect detection.

The software compares the obtained images with predefined parameters, for example, allowing it to identify defects, measure dimensions, and perform other critical quality checks.

Lighting and optics

To ensure optimal image quality and visibility, machine vision systems make use of lighting and optics techniques.

These lighting, can include tailored illumination and light setups, such as ring lights or backlighting, to enhance contrast and highlight specific features for inspection.

Optics, such as lenses and filters, can be selected to meet specific field-of-view or magnification requirements.

Components of a machine vision system

Cognex optical vision inspection systems consist of various essential components that work together to enable precise and reliable system integration for inspections of defective automotive parts.

These components include cameras and sensors, image inspection equipment and software, and industrial cameras, lighting and optics setups.

Cameras

The cameras used in Cognex' optical system are high-resolution camera devices capable of capturing detailed images or video streams of the products or components being inspected.

These cameras come in different models, offering a range and combination of resolutions, frame rates, and camera interface options to suit the specific requirements of the application.

They are designed to provide exceptional image quality and clarity, ensuring accurate analysis and detection of defects.

Sensors

Sensors play a crucial role in Cognex optical systems, as they allow the system to perform at optimal levels.

These sensors can be proximity sensors, light sensors, or even temperature sensors, depending on the specific needs of the production line and environment.

By providing vital feedback and data, sensors enable the system to adapt and respond to changes in real-time, ensuring consistent and reliable performance.

Barcode Readers | Certified Cognex Distributor

Cognex barcode reader

Cognex barcode readers are advanced devices used for reading distance capturing and decoding barcodes. They are a part of the product lineup from Cognex Corporation, a company renowned for its expertise in machine vision and industrial reading technology code. These barcodes readers are designed to efficiently and accurately read wide options of barcode types, including:

Traditional 1D barcodes

Complex 2D codes

Cognex barcode readers support various connectivity options, including USB interfaces for easy integration with different systems.

Barcode scanner can read on glossy surfaces on production line, curved surface, 2d code, qr codes and other. Companies can benefits from those system devices that scan code in tight spaces and quiet zone. Barcode scanner’ greater depth is 2d code reader, captured image

Barcode reader benefits

Durability and Reliability

Cognex barcode scanner systems are built with a rugged design to endure industrial conditions, delivering sustained high performance. Key attributes include:

Robust construction able to withstand:

Ambient light

Dust

Moisture

Mechanical stress

This makes them a dependable option for various industrial scanning needs.

Industry-Leading Read Rates

Cognex barcode scanners systems are renowned for their high read rates and excellent reading performance. This efficiency and speed is crucial in fast-paced industrial settings where every second counts.

They can accurately decode a wide codes options, including those that are hard to read due to damage, wear, or poor printing quality. This capability is essential for maintaining the high speed and accuracy of operations.

Advanced Technology and Design

These scanners feature advanced technology for enhanced functionality, including:

High speed and performance

Ease of use with intuitive setup and operation

Modular options for customization to specific industry needs

Additionally, Cognex barcode readers can interface with computers through a keyboard wedge, allowing seamless data input into applications.

This reduces the learning curve and extra costs for operators.

No Moving Parts

The absence of moving parts benefits industrial use by:

Reducing potential breakdowns

Lowering maintenance costs

This feature also boosts the overall durability and reliability of the system.

Cost Reduction and Performance Optimization

Cognex scanners enhance operational efficiency by:

Minimizing costs linked to misreads and downtime

Increasing throughput for greater work volume in less time

Improving inventory management and reducing waste through accurate traceability

Variety of Options

Cognex offers a wide range of scanners suitable for different industrial processes, including:

Fixed-mount scanners for stationary points

Handheld scanners for mobility and versatility

Verifiers for quality standard compliance

ESD-safe scanners designed for environments prone to electrostatic discharge

Different barcode scanners types

Cognex DataMan 70 series

The DataMan 70 series excels in reading 1D and 2D barcodes, particularly beneficial for indexed or high-speed environments. Features include:

High read rates

Compact design

Enhanced image formation

This model is especially effective in manufacturing and logistics applications involving fast-moving items.

DataMan 470 series

The DataMan 470 series handles complex, high-throughput manufacturing and logistics applications with ease. Key features include:

Multi-core processing capability

Advanced imaging technology and high-resolution sensors

Advanced decoding algorithms

Easy setup for maximum coverage, speed, and ease of use

DataMan 370 series

DataMan 370 series scanners are adept at managing difficult direct part mark (DPM) and label-based applications. They feature double the computing power of traditional readers, facilitating:

Faster decode speeds

Higher throughput

DataMan 280 Series

The DataMan 280 is designed for a range of code-reading scenarios across industrial and logistics facilities, enhancing traceability and efficiency with the fastest read rates.

Cognex DataMan 150/260 series

These fixed-mount, image-based barcode readers handle:

1D linear barcodes

Higher-density 2D matrix codes

Direct part mark (DPM) codes

Dataman 8050 Series

DataMan 8050 handheld scanners excel in reading well-marked 1D and 2D barcodes, including DPM codes, using patented decoding algorithms in challenging production settings.

Dataman 260 Series

The DataMan 260 Series supports a wide range of reading needs and includes options for:

High-speed, slow-speed, multiple-code, omni-directional readingDISCOVER COGNEX BARCODE READERS

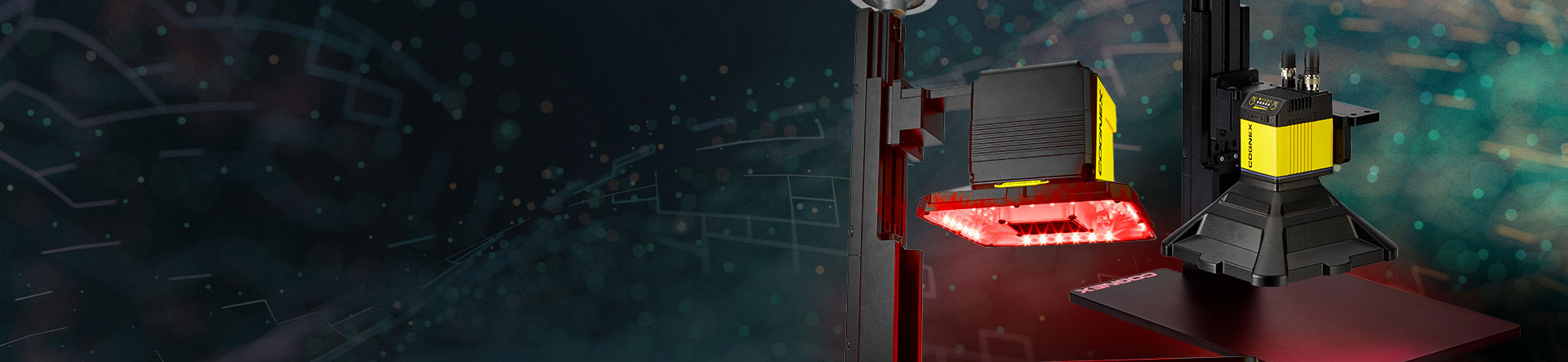

Fixed-mount Barcode Readers

Cognex DataMan fixed-mount barcode readers provide superior 1D and 2D code reading capabilities. DataMan barcode readers are the appropriate answer for complex industrial and logistics code applications because to their advanced technology, processing capability, adaptability, and ease of use.

DataMan 470 Series

DataMan 580

DataMan 370 Series

DataMan 280 Series

DataMan 150/260 Series

DataMan 70 Series

Handheld Barcode Readers

Handheld scanners provide flexibility and mobility, essential for industries requiring on-the-go scanning capabilities, such as:

Automotive

Medical devices

Electronics

Aerospace

Product security

Barcode Verifiers

Barcode verification is the process of evaluating the quality of 1D, 2D, and DPM codes. A growing number of regulated sectors require barcode verification. Barcode verifiers guide users through the marking process, ensuring that codes fulfill minimal quality criteria. Cognex barcode verifiers combine high-quality optics, powerful algorithms, and easy software to demonstrate adherence to industry standards.

DataMan 475V

DataMan 475VS Series

DataMan 8072V

In-Sight 7905V Series

Webscan Barcode Verifiers

Why choose Cognex barcode scanner?

Patented Algorithms

Cognex barcode readers are equipped with proprietary algorithms that enhance their image reading capabilities.

These algorithms enable the reader for exceptionally accurate image capture, reading, and decoding even in challenging conditions such as:

External lighting

Adverse settings

This sets them apart from other barcode readers in the market.

Customizable Software and Hardware

Cognex offers a range of customizable software and hardware options, allowing users to tailor the barcode scan and code barcode reader up to specific application requirements.

This level large depth of customization ensures that the scan and reading of objects by the various code barcode readers can be optimally configured for maximum efficiency in diverse industrial environments.

Unmatched Code Reading Capabilities

These code readers are renowned for their excellent performance on low-quality codes and their ability to read codes that other readers might miss, including:

Reading codes at high speeds

Decoding codes at various angles

Capturing codes in poor lighting conditions

This makes their methods of reading highly reliable in dynamic operational settings.

Global Support and Service Network

Cognex has a widespread support and service network, ensuring that customers have access to expert assistance and maintenance services no matter where they are located. This global network provides peace of mind and ensures minimal downtime.

Strong Industry Reputation

With a long-standing presence in the barcodes industry, Cognex has built a reputation for quality, high resolution, speed and reliability barcodes throughout. Many industries trust Cognex for critical barcode reading applications, reflecting the company's commitment to the industry standards of excellence and innovation in barcodes.

Advanced Connectivity Options

Cognex barcode scanners and image readers support various connectivity options, including:

Wireless

Ethernet communication

This flexibility allows for seamless integration into modern industrial IoT environments, enhancing data collection and process efficiency. These connectivity options also enhance data capture capabilities, ensuring efficient and accurate data collection in industrial environments.

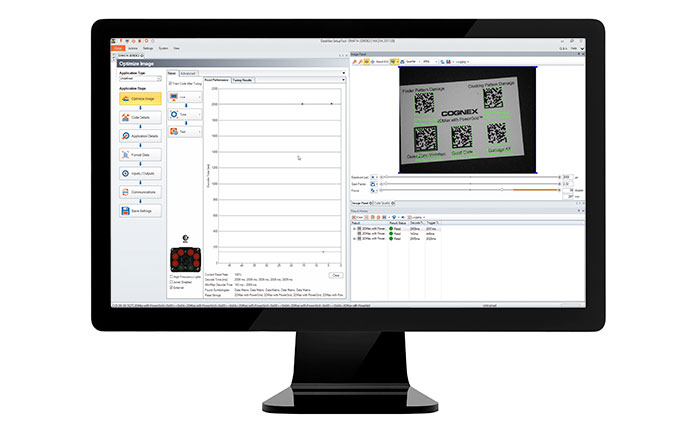

DataMan Software Suite

The DataMan software suite, specific to Cognex barcode code scanners, offers powerful tools for setup easy installation and management of their barcode code readers. This software package enhances the whole code reader user experience by providing intuitive interfaces and advanced and full image capture and analytics capabilities.

Industrial applications for barcode scanners systems

Manufacturing and Assembly Lines

Barcode readers are extensively used in manufacturing facilities to track parts and products as they move through the assembly and production line. They help in ensuring that:

The right components are used

Products are assembled correctly

This tracking and marking system is crucial for:

Quality control

Maintaining a detailed production record

Logistics and Supply Chain Management

In the logistics sector, handheld barcode scanners offer great benefits for tracking shipments and inventory. They are used for:

Scanning goods as they are received

Storing and shipping goods

Using barcode scanners ensures:

Accurate inventory management

Efficient warehouse operations

Reduced errors in order fulfillment

Pharmaceuticals and Healthcare

The pharmaceutical and medical sectors device manufacturing and healthcare settings, barcode readers are used for marking methods tracking drugs, devices and medical equipment. They help in maintaining the integrity and speed of the production chain, ensuring that the right medication or medical device always reaches the right patient, and in marking and managing inventory in hospitals and pharmacies.

Automotive Industry

In pharmaceutical manufacturing and healthcare settings, barcode readers are used for tracking drugs, devices, and medical equipment. They help in:

Maintaining the integrity and speed of the production chain

Ensuring the right medication or medical device reaches the right patient

Managing inventory in hospitals and pharmacies

Food and Beverage Industry

Barcode readers play a significant role in the food and beverage industry by:

Tracking ingredients

Managing inventory

Ensuring proper labeling of products

They are also crucial for:

Traceability purposes

Complying with regulatory requirements for food safety

Case Study of Streamlining Operations in Pharmaceutical Manufacturing

A leading pharmaceutical company faced challenges in tracking and managing its vast inventory of medication and supplies. The company implemented Cognex barcode readers across their manufacturing and distribution centers. The integration of this technology led to:

Exceptional accuracy in scanning, even with hard-to-read or damaged labels

Reduced instances of mislabeled or misplaced items

Streamlined inventory processes, leading to significant time savings and reduced operational costs

The robust and durable design of the readers was ideal for the demanding conditions of a pharmaceutical environment. The successful implementation not only enhanced operational efficiency but also reinforced the company's commitment to quality and safety in healthcare.

Where can I find a laser barcode scanners?

A barcode reader, also known as a barcode scanner, is an input device that reads information from a barcode. Barcodes are available in a variety of 1D and 2D symbologies and are used to:

Track nearly every item in industry and commerce

Manage inventory

Verify product legitimacy

Barcode readers collect and report massive volumes of data in a timely, accurate, and cost-effective manner. They form the backbone of industrial networking, from factory automation to retail point of sale (POS).

In retail, devices such as RF guns or raster laser barcode scanners are still used. However, manufacturing and logistics firms have shifted from laser systems to image-based barcode scanners for enhanced efficiency and accuracy.

FIXED-MOUNT BARCODE SCANNERS

DataMan 370 series

DataMan 470 series

DataMan 280 Series

Cognex DataMan 150/260 series

Dataman 150 Series

Cognex DataMan 70 series

HANDHELD BARCODE SCANNERS

Dataman 8700 Series

Dataman 8050 Series

ESD-SAFE BARCODE SCANNERS

Electrostatic discharge (ESD) can damage or destroy electronic components, create fires, and cause data loss. To prevent electrostatic discharge, an ESD-safe barcode scanner code reader, and code barcode scanner reader now combines ESD-safe polymers for all enclosure parts with an antistatic coating for all optical parts.

Image processing software

Machine vision systems rely on advanced image processing software, such as Cognex VisionPro, to analyze snapped images or video streams.

This software offers a comprehensive set of tools and algorithms for image enhancement, pattern recognition, feature extraction, and defect detection.

It enables users to define inspection parameters, set tolerances, and configure specific measurement criteria to ensure accurate and efficient inspections.

Benefits of implementing a vision inspection system

Improved quality control

The implementation of machine optical systems brings forth numerous benefits to manufacturing industries, for example, revolutionizing industrial quality control processes and enhancing manufacturing efficiency.

One of the key benefits of implementing Cognex optical systems is the significant improvement in quality control.

High quality detection

These systems enable the detection of even the tiniest flaws and deviations in products or other electronic components themselves, ensuring that only items meeting the highest quality standards are passed through the manufacturing process.

With advanced algorithms and high-resolution cameras, machine vision systems offer exceptional accuracy and reliability in defect detection, reducing the risk of faulty products reaching the market and protecting brand reputation.

Increased efficiency in manufacturing processes

Machine vision systems streamline manufacturing processes by automating inspections and reducing the need for manual labor.

These vision inspection systems can perform multiple inspections together at high speeds, capable of analyzing thousands of parts per minute.

By eliminating the need for manual inspections defective parts, which are prone to errors and inconsistencies, Cognex' vision inspection systems optimize fabrication, improve efficiency further, reduce cycle times, and increase throughput. Manufacturers benefit from accelerated throughput rates, improved productivity, and reduced production costs.

Furthermore, machine vision systems can be seamlessly integrated into existing production lines, enhancing process efficiency and reducing the time consuming overall downtime.

The real-time feedback and operational guidance provided by industrial cameras within the system allows operational guidance for immediate corrective actions to improve efficiency, preventing bottlenecks and improving overall operational efficiency.

Choosing the right machine vision system

Choosing the right machine vision systems is vital to ensure optimal performance and meet the specific requirements of your application by understanding system capabilities.

Consider the following factors when selecting a right vision system. Several factors should be taken into account when choosing a machine vision system or systems.

Assessing application requirements

Assess the nature of your application and the specific inspection requirements. Determine the types of defects or anomalies you need to detect to inspect products, the desired level of accuracy and speed, and any specific industry regulations or standards to adhere to.

Evaluating physical constraints

Consider the physical constraints of your production environment. Evaluate the space available for installing multiple cameras, and lighting setups, as well as any environmental conditions that may impact system performance.

Budget considerations

Budget is another crucial aspect to consider. Cognex offers a range of vision systems with varying features and capabilities, each with different price points. Assess your budgetary constraints and align them with the specific needs of your application.

Different types of machine vision systems

Cognex offers a diverse range of inspection systems and vision systems designed to address various inspection and quality control needs. These include 2D vision systems, 3D vision systems, barcode readers, line scan cameras, and machine vision sensors.

2D vision systems: basic inspections and accuracy

2D vision systems are widely used for basic inspections, defect detection, and dimensional measurements. They provide efficient and accurate results for a wide range of applications.

3D vision systems: precision in depth perception

3D vision systems, on the other hand, allow for depth perception and enable precise measurements of object height, volume, and shape.

They are ideal for applications where 3D information is crucial, such as robotics, bin picking, packaging and surface inspection of packaging.

Advanced features and capabilities of machine vision systems

Machine vision systems offer a range of various devices with advanced features and capabilities, including real-time monitoring, that enhance their performance and expand their applications in various industries.

Machine learning and deep learning in machine vision systems

Machine vision systems utilize machine learning and deep learning technologies to improve inspection accuracy and adaptability.

Machine learning algorithms enable the system to learn from previous inspection data, identify patterns in data, and continuously improve upon its detection capabilities.

Advantages of deep learning algorithms

Deep learning algorithms, with their ability to analyze large datasets and extract intricate features manufactured products, enhance the first vision system's ability to recognize complex defects and contrast in products.

By leveraging a combination of these technologies, machine vision systems can achieve higher detection rates and lower false positive rates, improving overall inspection reliability.

3D Vision and Dimensional Measurement

Cognex optical systems incorporate 3D vision technologies to enable precise dimensional measurement and position and volume calculations.

By capturing depth information along with 2D images, the system and camera can accurately determine and measure the height, width focal length, shape and depth of objects, ensuring compliance with dimensional specifications.

This capability is particularly useful in applications such as robotics, where precise measurements are essential for tasks like pick and place operations.

With 3D vision capabilities, machine vision systems can accurately detect and classify objects based on their geometrical characteristics, providing enhanced inspection capabilities industrial robots and opening doors to a wide range of applications.

Surface Inspections and Texture Analysis

In addition to dimensional measurement, machine vision systems offer the ability to perform surface inspections and analyze complex textures using advanced image analysis techniques.

This technology allows the system to detect and measure surface defects, scratches, discolorations surface scratches, or other irregularities that may impact product quality.

By leveraging 3D vision and dimensional measurement capabilities, machine vision systems provide manufacturers with powerful tools to ensure product integrity, streamline processes, and meet quality standards.

"

"

Get product pricing

Cognex delivers the widest range of image-based factory automation and distribution products to help companies like you ensure error-free production, lower costs, and manage your supply chain