Machine Vision Supplier

What are Machine Vision Systems?

Machine vision systems are advanced technological vision solutions, that combine cameras, software algorithms, and hardware components to automate visual tasks and provide real-time analysis of the images captured, or video streams. Mecatronique Solutions offers turnkey solutions with their software products for military industries, manufacturing company and other industries.

These human vision systems mimic the human eye and vision capabilities by capturing images or videos and then processing them to extract valuable information for decision-making, quality control, and inspection purposes. . Machine vision technologies and solutions are widely used in various industries, including manufacturing, the automotive industry, electronics, pharmaceuticals, and more.

Importance of Machine Vision Systems in Industrial Applications

Machine vision systems play a vital role in industrial applications, revolutionizing manufacturing processes and enhancing operational efficiency. By automating visual tasks, these systems can perform accurate quality control inspections, identify defects, measure dimensions, and read barcodes or labels, all with consistency and speed.

This reduces the risk of human error, increases productivity, and ensures that products meet high-quality standards.

Real-time monitoring of production lines

The implementation and automation of machine vision software also allows for real-time monitoring of production lines, ensuring smooth operations and minimizing costly downtime. With their ability to quickly capture and analyze images, machine vision software systems contribute to improved process control, optimized workflows, and faster decision-making.

Detecting and preventing defects early

Furthermore, machine vision systems contribute to reducing waste and increasing cost savings by detecting and preventing defects early in the production process. They enable manufacturers to identify faulty or non-compliant products, facilitating their removal from the production line and avoiding potential customer dissatisfaction or recalls.

Overall, the importance of machine vision software in industrial applications is undeniable. Their ability to automate visual tasks, enhance quality control, and optimize manufacturing processes make them invaluable tools for businesses and industries striving for efficiency, accuracy, and improved product quality.

2D Machine Vision Systems overview

2D machine vision solutions utilize cameras and advanced software algorithms to both capture images, and analyze two-dimensional deep learning technology for images or video streams. These systems play a crucial role in various medical imaging industrial applications, providing reliable inspection, identification, and measurement capabilities.

By analyzing 2D images, these systems can detect defects, perform quality control checks, measure dimensions, and verify the presence of specific features or characteristics.

High-resolution camera

The operation of 2D machine vision technology typically involves a high-resolution camera that captures images of the objects of interest. These images are then processed using sophisticated software algorithms to extract relevant information.

The extracted inspection data is analyzed, and predefined criteria are applied to make automated decisions based on the inspection requirements. This allows for fast and accurate identification of anomalies or deviations from the desired specifications.

Applications of 2D Machine Vision Systems in Industrial Settings

2D machine vision technology find applications across a wide range of different industries throughout. These systems and solutions in machine vision market are extensively used in manufacturing industry for precise control and inspection purposes, ensuring that products meet specified standards.

Maintaining strict quality control processes

In industries such various products and services such as automotive manufacturing, electronics assembly, or pharmaceutical production, 2D vision sensors smart cameras can identify defects, such as scratches, cracks, misalignments, or missing components. This enables companies to maintain strict precisely control processes and deliver products that adhere to customer expectations.

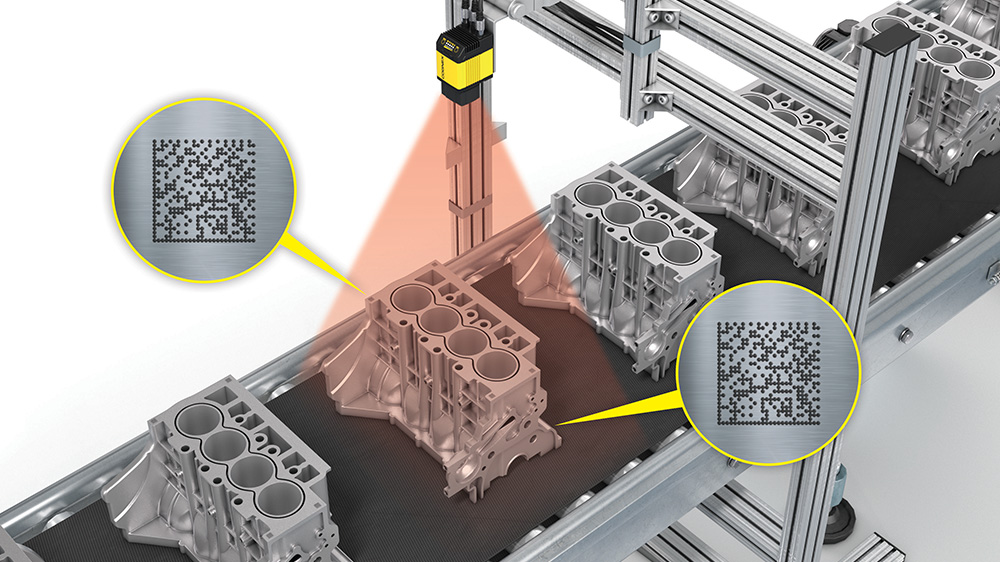

Scanning and decoding polyvalence

Another important application of 2D vision sensors is barcode reading and verification. These systems excel in accurately scanning and decoding barcodes, whether on product packaging, shipping labels, or components.

By verifying the correctness and readability of barcodes, businesses can improve inventory management, track products throughout the supply chain, and enhance overall operational efficiency.

Ensuring accuracy and reducing manual efforts

Moreover, 2D machine vision systems find utility in optical character recognition (OCR), where they can decipher and extract text from images or documents. This is advantageous in applications such as document digitization, automated data entry, or reading printed information on labels, ensuring accuracy and reducing manual efforts.

The versatility and reliability of 2D machine vision systems make them indispensable in numerous and industrial production settings, where accuracy, speed, and efficiency are paramount.

Machine Vision Systems Overview

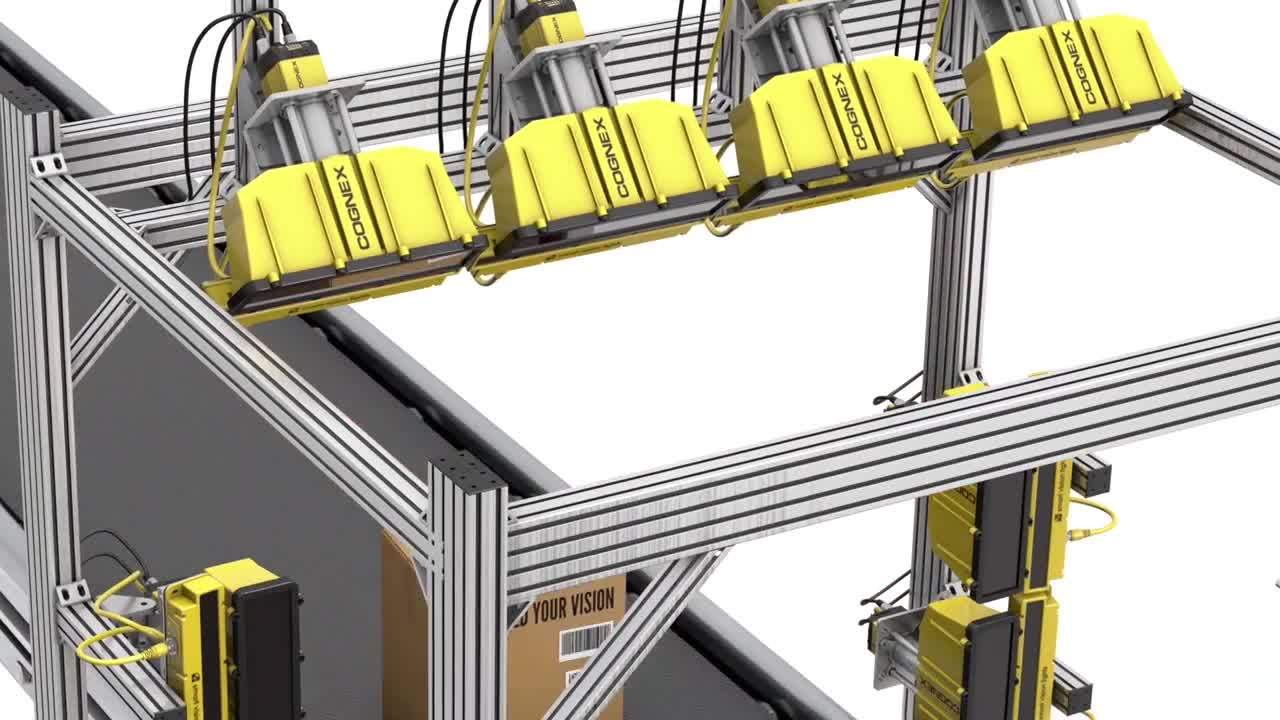

Machine vision systems play a crucial role in various industries, providing automated visual inspection and analysis capabilities. These systems utilize advanced imaging technologies smart cameras and computer algorithms to process and interpret images or video streams, enabling companies using them to perform tasks that would otherwise require human intervention.

A machine vision system typically consists of a camera or multiple cameras, image processing software, and hardware components for image acquisition and analysis.

Automate visual tasks on predefined criteria

The primary goal of machine vision systems is to automate visual tasks, such as quality control, measurement, object recognition automated visual inspection, and defect detection. By capturing images or videos of objects or scenes, these systems can identify and classify objects, perform measurements, detect anomalies, and make decisions based on predefined criteria.

From manufacturing lines and packaging to medical equipment and diagnostics, machine vision systems are employed in numerous industries to make companies enhance productivity, accuracy, and efficiency.

Make informed decisions with visual inspection

Machine vision systems rely on various technologies, including cameras with different sensor types (such as CCD or CMOS), specialized lighting setups, and sophisticated algorithms for image processing. The cameras capture high-quality images, which are then analyzed by the software to extract meaningful information and make informed decisions.

The extracted data can be used for various purposes, such as ensuring product quality, enhancing process control, reducing errors, and improving overall operational efficiency.

As advancements continue in the machine vision market using learning, deep learning, and artificial intelligence, machine vision systems are becoming more intelligent, enabling them to handle complex tasks and adapt to dynamic environments.

The applications and potential uses of machine vision systems are vast, making them a crucial component of the digital transformation and Industry 4.0 initiatives.

Key Considerations When Choosing Machine Vision System Suppliers

Choosing the right machine vision system supplier is a critical decision that can greatly impact the success of an implementation. It is essential to evaluate various factors when considering different suppliers to ensure the selection of the most suitable partner for a specific application.

Expertise and experience in the field

One key consideration is the supplier's expertise and experience in the field. A reputable supplier company will have a proven track record of delivering high-quality machine vision systems, backed by a deep understanding of the industry and its unique requirements.

It is essential to assess the supplier's background, knowledge, and the scope of their previous projects to gauge their capability in meeting specific application needs.

Comprehensive support

Another crucial aspect is the supplier's ability to provide comprehensive support services, including consultation, installation, and ongoing maintenance services. The supplier should have a knowledgeable and responsive support team that can provide technical assistance in system integration, troubleshooting, and upgrades. Timely support can minimize downtime and ensure the smooth operation of the system.

Selection of machine vision systems

Additionally, the availability and range of products offered by the supplier should be evaluated. It is advisable to choose a supplier that offers a diverse selection of machine vision systems, cameras, and components, providing flexibility and scalability for future needs.

The supplier's product portfolio should align with the company and application requirements, encompassing all hardware solutions with the necessary features, performance levels, and integration capabilities.

Reputation and customer reviews

Lastly, considering the supplier's reputation and customer reviews can provide valuable insights into their reliability, customer satisfaction, and service quality. Checking references and testimonials can help gauge the supplier's credibility and extensive experience and build confidence in their ability to provide a successful implementation.

Overall, selecting the right machine vision system supplier requires a thorough evaluation of expertise, support capabilities, product offerings, and reputation. By considering these key factors, businesses and machine vision companies can make an informed decision and forge a valuable partnership that paves the way for seamless integration and long-term success.

Different Types of Machine Vision Systems for Industrial Applications

2D Machine Vision Systems

2D machine vision systems are widely used in industrial applications for tasks such as inspection, identification, and measurement. These systems capture 2D images or video streams and analyze them to extract valuable information for decision-making.

Perform various tasks with precision

Using cameras with advanced imaging technology, combined with powerful software algorithms, 2D machine vision systems can now identify objects, and inspect objects, detect defects, measure dimensions, and perform various other tasks with precision.

Vision systems versatility

One of the key advantages of 2D machine vision systems is their versatility. They can be utilized in a wide range of industries such as automotive, electronics, packaging, and pharmaceuticals. In these sectors, 2D machine vision systems are employed for precise control, ensuring products meet strict standards, and for enhancing operational efficiency by automating visual inspection tasks.

Rapid identification and classification

These machine vision applications and systems are also valuable for barcode reading, optical character recognition (OCR), and label verification applications. With their high-speed image capture and processing capabilities, 2D machine vision applications and software excel in tasks that require rapid identification and classification of objects, such as on production and assembly lines, or in logistics operations.

Cost-effective solutions

While 2D machine vision systems lack depth perception compared to 3D computer vision systems, they remain highly capable and cost-effective solutions for many industrial applications. Their flexibility, ease of integration, and proven performance make them a popular choice for businesses seeking reliable and efficient machine vision solutions.

3D Machine Vision Systems

3D machine vision systems enable the capture and analyse of three-dimensional information from objects or scenes. These deep learning systems utilize specialized cameras and algorithms to reconstruct the geometry and depth of the captured images, bringing an additional dimension to the analysis process.

Deep learning and vision system

Deep learning in vision cameras involves using neural networks to automatically identify and classify objects within images captured by the camera. These systems can be trained on large datasets to recognize patterns, detect anomalies, and provide real-time analysis. Advanced algorithms enable the cameras to perform tasks such, object detection, and scene understanding, enhancing their functionality and accuracy.

By capturing 3D data, these vision systems offer enhanced capabilities in inspection, measurement, robotic guidance, and object and facial recognition too.

Accurate and detailed depth information

One of the key advantages of 3D machine vision systems is their ability to provide accurate and detailed depth information. This depth perception allows for the precise measurement of object dimensions, detection of surface defects, and detection of intricate features that may not be possible with conventional 2D imaging systems alone.

Invaluable in automation tasks

3D machine vision cameras are widely employed in industries such as automotive, aerospace, electronics, and food processing, where high-precision dimensional inspection is critical. These imaging systems are also instrumental in robotic guidance and automation applications for power supplies system automation equipment company.

By providing the necessary depth data, company can benefits enable robots to interact with the environment more effectively, manipulate objects with precision such as frame grabbers, and navigate complex environments. This makes them invaluable in tasks such as bin picking, assembly line operations, and warehouse automation systems.

Ensure stringent quality control standards

Although 3D machine vision cameras may have higher implementation costs and complexity compared to their 2D counterparts, their capability to capture detailed depth information opens up new possibilities in various industrial applications. Vision solutions are great for company that needs solutions automation systems for their equipment

As technology continues to advance, 3D and machine vision technologies and cameras are expected to play an increasingly significant role in automating complex manufacturing processes and ensuring stringent quality control standards. This system integration is great for image processing, software automation making a perfect software system for manufacturing company that needs automation equipment system.

Get in touch

Fill out the form below to get in touch with our team.